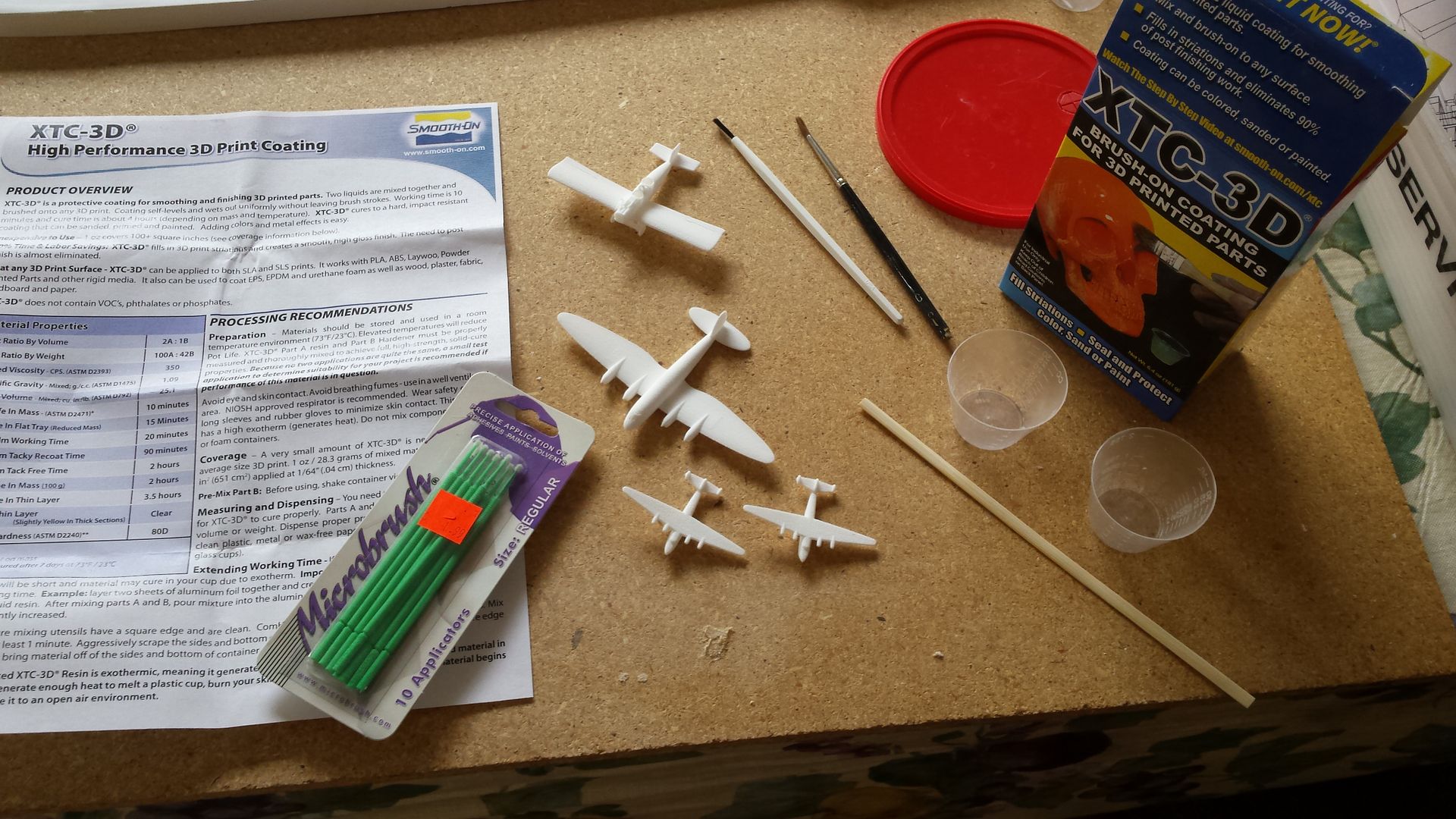

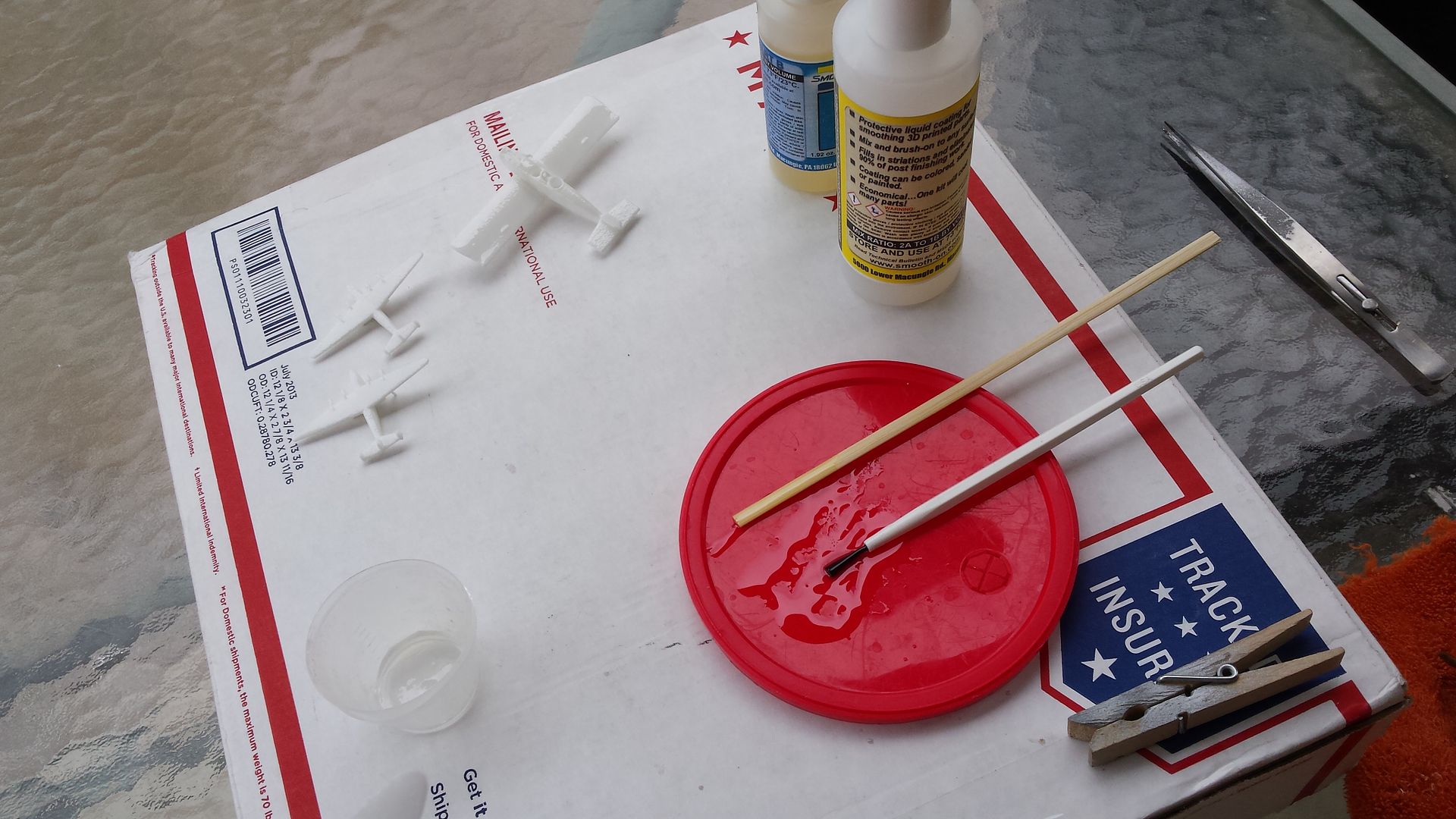

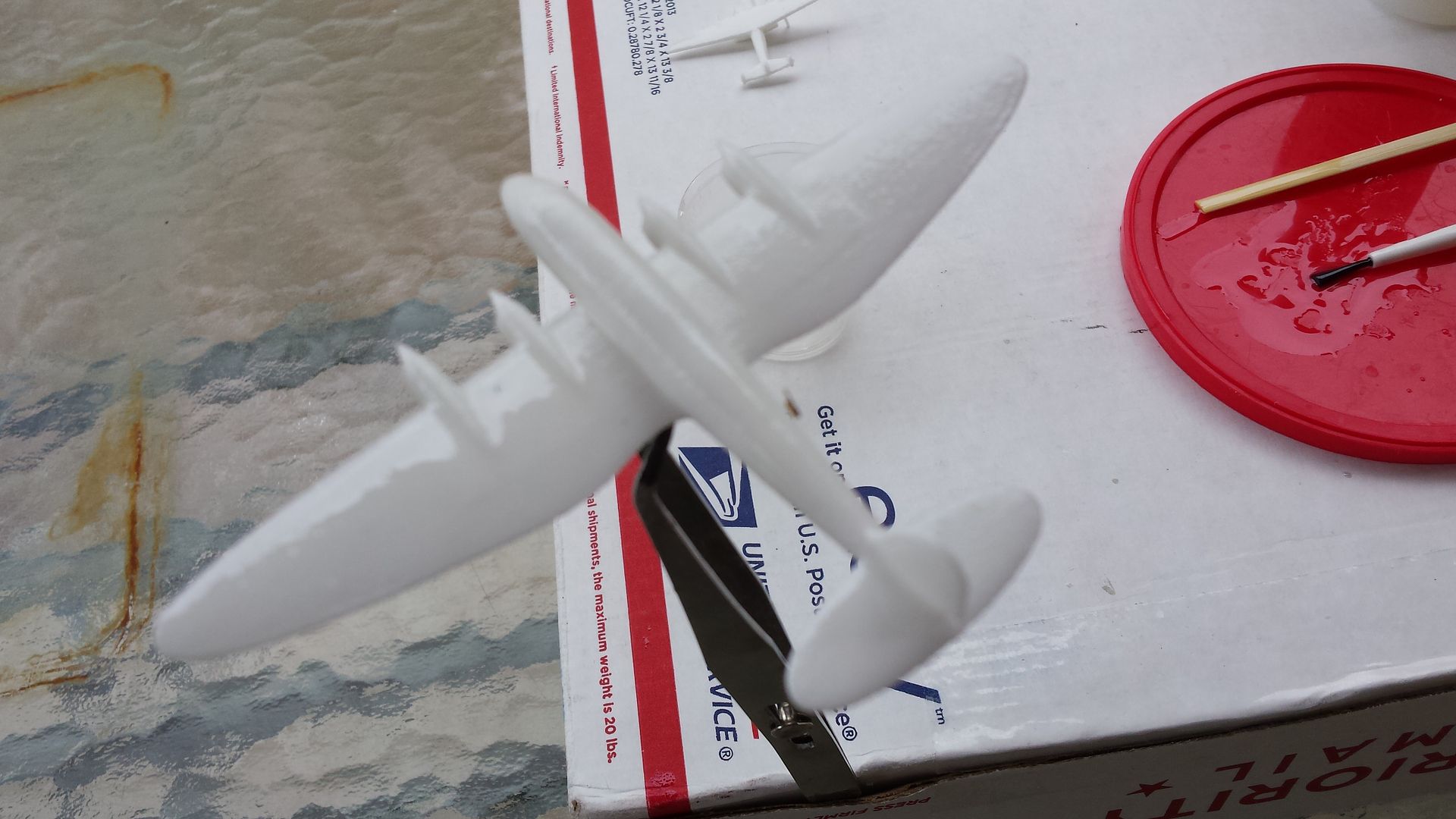

Don't know if anyone else already tried this ( I haven't since I just found out!) but a friend of mine had coated a few 1/144th scale Shapeways WWI planes with this liquid resin. Last week he showed me a Fokker DII and the surfaces were as smooth as any plastic injection kit, and from what I could see with absolutely no loss of detail.. Apparently he had used a liquid resin/epoxy called XTC-3D and while he said it stank to the high heavens it also closed every pore on the WSF models in one coat.

I tried ordering it from the US last week but haven't got a response yet.

For those wanting to check it out for themselves here's a link I found

http://www.smooth-on.com/Epoxy-Coati...429/index.html

Reply With Quote

Reply With Quote

Bookmarks